본문

| EPS(Electric Power Steering) system

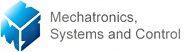

Electric Power Steering(EPS) system is a motor supported power steering system that helps provide the driver with a lightweight and convenient steering feel. Because the steering system interacts with human hands, which can be sensitive, designing a good controller is subtle and challenging problem. We focus on all process of controller design of EPS system including modeling and parameter identification, stability analysis, steering feeling and new approach of controller structure.

Fig. 1. Schematic structure of the EPS system and typical structure of a conventional EPS controller

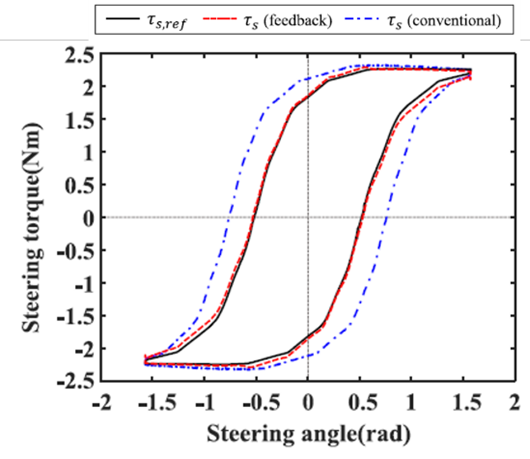

Target steering torque feedback controller

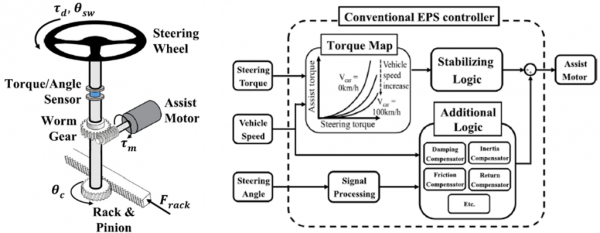

To overcome the limitation of conventional EPS controller, we propose a model based controller that is separated into a logic to generate steering feeling and a feedback logic to implement the generated steering feel to the driver. Since the nonlinear torque map and additional logic for steering feel tuning are not included in the feedback controller, it is possible to analyze the system stability and to design a controller using linear control theory without linear approximation. The steering feel tuning and a controller design ensuring the stability and performance of the system can be decoupled. With the suggested structure of the EPS controller, once the feedback controller is designed to ensure the stability and performance of the system in advance, the steering feel can be freely designed based on the feedback controller environment. Fig. 2. Structure of a target steering torque feedback controller

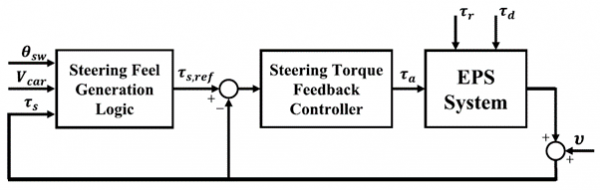

Open loop transfer function of EPS system must have a large magnitude in the low-frequency range in which the target steering torque and disturbance are formed. In the low-frequency range, the torque sensor value is close to the target torque, and the influence of disturbance that includes the driver torque and rack force is minimized. On the contrary, open loop transfer function should have a small magnitude in the high-frequency range to eliminate the noise signals.

Fig. 3. Loop-shaping guideline for an EPS controller

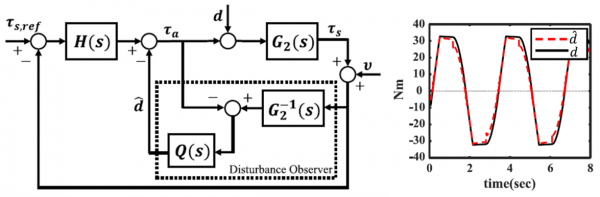

One of the important factors that determines the performance of the feedback controller is how well it suppresses the effect of disturbance. The rack force and driver torque of the EPS system are considered as a disturbance. Since the rack force generally has a very large value relative to the target steering torque, especially in the parking state, it is difficult to obtain the desired tracking performance via disturbance suppression of the feedback controller alone. Therefore, the disturbance observer(DOB) is utilized to prevent the performance degradation of the feedback controller due to large disturbances.

Fig. 4. Steering torque feedback controller with a disturbance observer

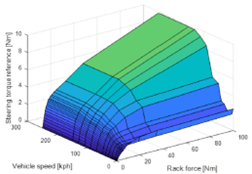

Steering feel generation logic

To create the steering feel generation logic, an external rack-force-based torque map is used. The rack force estimator calculates the rack force based on EPS system states, and the torque map determines the target steering torque based on the estimated rack force. The rack-force-based steering feel generation logic can deliver road condition information because the rack force is a raw signal that contains all information(dry, wet, frozen and vibration) transmitted from the road surface to the tire. The driver will always feel a certain portion of the rack force, allowing the driver to detect changes in road conditions.

Fig. 5. Steering torque map using the rack force

Fig. 6. Comparison between the reference torque and measured steering torque from system with conventional EPS controller and target steering torque feedback controller

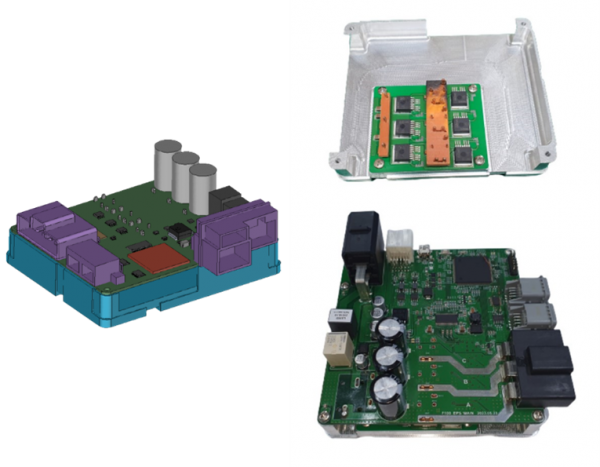

Fig. 7. EPS ECU design

<Reference> [1] Lee, Dongwook, Kyung-Soo Kim, and Soohyun Kim. "Controller design of an electric power steering system." IEEE Transactions on Control Systems Technology 26.2 (2017): 748-755. [2] Lee, Dongwook, Kyung-soo Kim, and Minwoo Han. "Model-based analysis of the hysteresis curve of an electric power steering system." 2020 20th International Conference on Control, Automation and Systems (ICCAS). IEEE, 2020. [3] Lee, Dongwook, Byeonggwan Jang, Minwoo Han, and Kyung-Soo Kim. "A new controller design method for an electric power steering system based on a target steering torque feedback controller." Control Engineering Practice 106 (2021): 104658.

[4] Jang, Byeonggwan, Dongwook Lee, Kyuwon Kim, and Kyung-Soo Kim. "Road Torque Modeling for Electric Power Steering Systems." International Journal of Automotive Technology 23.3 (2022): 765-773.

|